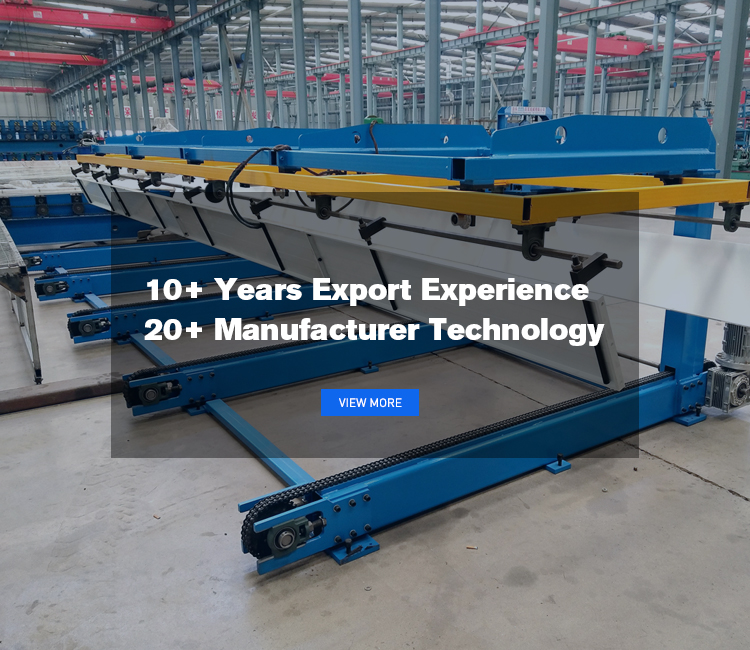

ZhongHeng Machine Manufacture Co.,Ltd

CANGZHOU ZhongHeng Machine Manufacture Co.,ltd is a professional

manufacturer and exporter which has its own factory and also

cooperate with several production factories and associated

enterprises, concerning with the design, development and production

of cold roll forming machines,material of building. It is located in northwest of CangZhou, as

a long history of cold roll forming machine production base. All

products comply with international quality standards and are

greatly appreciated in variety of different markets throughout the

world, Our company is organized and run as a modern enterprise

system. We specialize in the automated production line of sheet

cold roll forming machines. We are able to provide an integral

resolution schema of cold roll forming system through a combination

of advanced system design and equipment. Based on our advanced

research and commercial team, we are able to research and

development, manufacturing and sale of standard and non-standard

cold roll forming equipment for our clients world widely. Besides

this we Cooperate with professional factories for nail making

machine and livestock equipment.

We would like to invite you to come and join our to build our

mutual benefit.